UR10 reachability estimation using onshape.com

If you are interested in industrial automation and have not been living under a rock, you might have noticed a new category of robots coming into the price range of small and medium sized businesses over the last few years: Universal Robots' UR3/UR5/UR10, Baxter and Sawyer from Rethink Robotics and others like Kuka's LBR series.

These won't ever assemble the heavy parts of your car, but they have some distinct properties:

- Cheap: Dirt cheap if you think in industrial automation dimension. UR10 comes in a box for less than 30.000€. That is 3-5 times cheaper than typical installations have been ~5-10 years ago.

- Compliant: Means safe to work in proximity to humans without a cage in most cases. It basically brings common sense safety into the domain: You can (and will) build applications that inherently won't be able to seriously harm operators, co-workers or equipment.

- Easy (or easier) to setup, program and operate: It seems reasonable to have normal production staff at least operate the robot and reset error conditions. Staff who don't mind learning very basic graphical programming (think Basic without arithmetics) should also be able to write/enter programs. I can't see anyone demanding 6-figure wages for programming those robots. Sorry.

- Complete solution in a box: You get a robot, a programming/operating console, all the software (on that console) and licenses with the robot. There are no needed external components and no mandatory integration work to be done.

- Limited: Payload for the UR10 is 10kg. Range is 1300mm max.

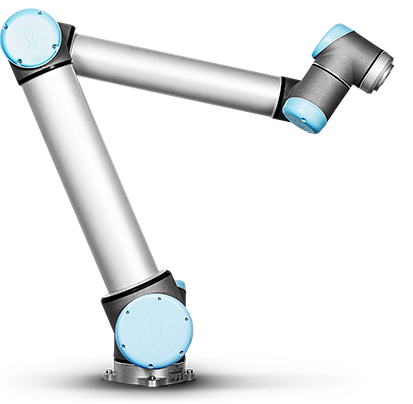

This is what the 10kg-payload UR10 looks like:

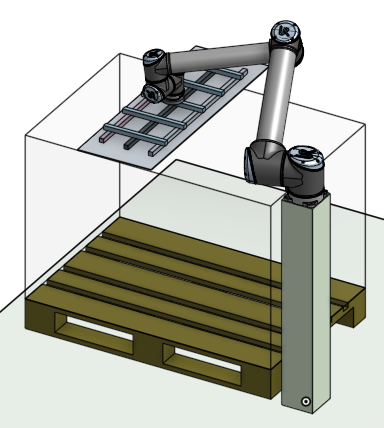

One of the questions that arise once you think about automating a production step with one of these is: Where can I put it and how far can it reach. Traditionally, your service provider would do that analysis. But with the cheap people entering the market, customers will want to do that themselves. I am one of those customers who value being able to do (or at least check) such an analysis themselves.

And astonishingly, you can do it rather easily - with free tools (as in free beer)!

Onshape is a CAD workbench that works in your webbrowser. And it works quite well for stuff like this! If you get an Onshape account, you can access my document UR10 reachability analysis:

Once you create a copy of that document, you can select parts attached to the tool of the robot and move it. Onshape interactively calculates the kinematic to move the robot joints. The way the model is setup, you should not be able to move the tool beyond the reachability of the robot. But - no guarantees!

The actual robot 3D model was taken from the UR10 product page. The joints that link and constraint the parts were added in Onshape.

Have fun playing with the robot - without having the robot!